Introduction to Container Transportation

ISO Shipping containers revolutionised shipping, allowing convenient transportation of one truck load of goods which could be stuffed into the container at shippers premises, collected by truck and taken to the ship and then offloaded from the ship at receiving port and then taken by truck to receiver’s premises. Containers may also be carried by rail.

Intermodal transportation is facilitated by the use of containers allowing the transport by different modes of transport namely ship, truck and rail.

The use of large vessels to serve lines between major ports led to container transport being very cost effective. The large vessels do not go to every port, but discharge at major hubs. A hub is a port where the container will be offloaded from one vessel and then collected by another vessel which serves different ports. Small vessels which make connections between smaller ports and the hub are called feeder vessels.

The ISO Container

Lets take a look at an ISO container. They are named as such because they must comply with a group of standards issued by the International Standards Organisation. There are many types of container, the basic sizes are 20ft length and 40ft length. They may be fully enclosed like the one in the above photograph which is now in a useless damaged condition, or they may be open top, flat rack, tank containers or reefer containers for carrying refrigerated goods.

Containers are described as they would sit on a truck. So the doors are the rear of the container. The four corners of the container have fittings. These are to allow the container to be secured or lifted into position.

Moving Containers in the Container Park

At the middle of the container sides at the lower edge are two forklift pockets. These are to allow forklifts to lift the container when EMPTY otherwise it gets damaged. Container parks may have large forlkifts which they use to stack containers. They may also have special container forklifts with a spreader that lifts the container from the corner fittings, these allow them to lift containers with cargo inside.

Large container parks and port container terminals have straddle carriers. These are mobile units which straddle the container and lift it from the top using a spreader trolley. They can stack containers also.

Overloading

Containers may carry typically 21,600 kg (20 ft) and 26,500 kg (40ft) although specially stengthened containers are available for heavier loads. Shippers may on occasion exceed these loads by not weighing the container on the truck using a truck weigh station. This is dangerous and may lead to the container being damaged. It is not rare to find overloading in practice however. Authorities should enforce against this when the truck is weighed at the port but not all ports do.

Stowage on the Ship

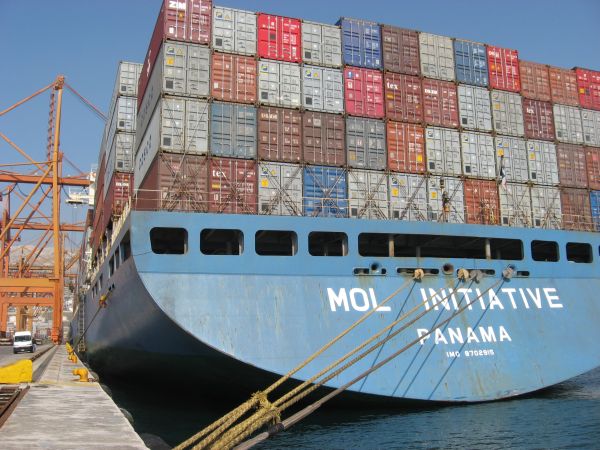

Looking forward on a container ship

In the above photo we can see a container ship. The ship can carry containers on deck but also has holds to stow containers in. The holds are closed with hatches. In the photo several are present but others have been removed to the quay by the gantry crane, in order to work cargo in the holds, as is the normal practice.

The holds of a container ship have cell guides. These are seen in the above photo as being vertical strips which make sure the container is aligned and stacked properly as it goes into the hold but also offer securing of the stack against movement.

Loading / Discharge of Containers by Gantry Crane

Spreader Trolley of Gantry Crane

The containers are usually discharged at dedicated container terminals using gantry cranes. The cranes move on two rail tracks which are parallel to the quay. The gantry cranes are each equipped with a spreader trolley which has lifting fittings that latch into the top parts of the corner fittings of the container.

Above we see the gantry crane lifting a container from the quay towards the ship. The spreader trolley ensures that the container is lifted correctly, spreading the load equally to each of the top four corners.

Above the crane is now positioining the container to go into the hold.

Securing Method of Containers on Board – Twist Locks

Lets look at the on board securing methods for containers. On the hatches of the ship are fittings which are practicaly identical to the corner fittings of the containers. In these fittings the crew place twist locks which you see indicated in the above photo.

The twist locks can be automatic, semi-automatic and manual. They are also placed in the top corner fittings of a container to secure one above to it.

Securing Method of Containers on Board – Lashing Rods and Turnbuckles

The second additional method of securing is via lashing rods and turnbuckles which you see in the above photo and which form an X using two of them. These are commonly placed at the lower tier. Larger ones will commonly secure the outboard containers of the lower and second tier. This securing method is done on the front and back of each single row of containers.

Click to pay with Credit Card

Click to pay with Credit Card